Contactless JET Dispenser

The application of our JET dispensing systems is process-independent and thus suitable for all processes. Combined with the quality feature Made in Japan, we guarantee the highest quality combined with the corresponding durability. With the use of our JET dispensers, we underline our promise to apply the most versatile liquids with high precision down to the smallest volume like no other.

MUSASHI SuperHiJet

Introducing the Musashi Super Hi Jet

Discover the next level of dispensing technology with the Musashi Super Hi Jet, engineered to exceed your high-viscosity application requirements. This advanced jet is specifically designed for specialized applications that demand exceptional precision and reliability.

Enhanced Jet for High-Viscosity Applications: Tailored for use across a broad viscosity spectrum up to 1,000,000 mPa·s, the Super Hi Jet offers unmatched versatility. From UV adhesives to solder and silicone pastes, this jet effortlessly handles the most challenging materials.

Excellent Position Accuracy: With its superior position accuracy, the Super Hi Jet ensures precise dispensing results essential for optimizing your production processes.

Customer-Friendly Rod Replacement: Understanding the importance of efficiency in production, Musashi Engineering has designed the Super Hi Jet to allow customers to easily replace the rod themselves, significantly reducing maintenance times and costs.

Hassle-Free Maintenance and User-Friendliness: Its thin and small design is not only space-saving but also ideally suited for multi-head systems. The maintenance-friendly construction ensures hassle-free upkeep.

Versatile Material Applications: Whether dispensing UV adhesives, solder paste, silicone, or other materials, the Super Hi Jet is your solution for reliable and accurate dispensing requirements.

Large Color Screen and Comprehensive Functionality: A large color screen enhances operability, while comprehensive functionality leaves nothing to be desired. From digital control of liquid delivery pressure to a memory function for dispensing parameters, the Super Hi Jet offers everything needed for efficient production.

Easy Integration and Remote Control: The Super Hi Jet is not only suitable for use in automatic machines but is also rack-mount capable. With USB and RS232C communication ports, all parameters can be sent and received, and operations can be remotely controlled.

Special Variants for Specific Applications: In addition to the standard model, the Super Hi Jet is also available as a Hot Melt Super Jet for PUR jetting and a Solder Jet variant for solder paste dispensing.

The Musashi Super Hi Jet redefines the boundaries of dispensing technology. With its outstanding performance and versatility, it is the ideal solution for your high-viscosity dispensing needs. Experience the future of precision dispensing with Musashi Engineering.

| Applicable liquid materials: | UF material, Ag paste, sealant, epoxy resin, grease, etc. |

| Viscosity range: | up to 1.000.000 mPa/s |

| Temperature setting range: | MAX: 100 Degree Celsius |

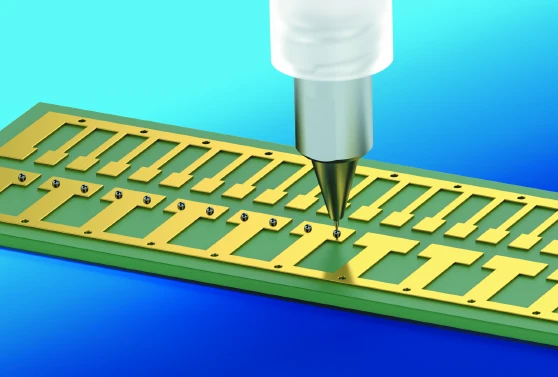

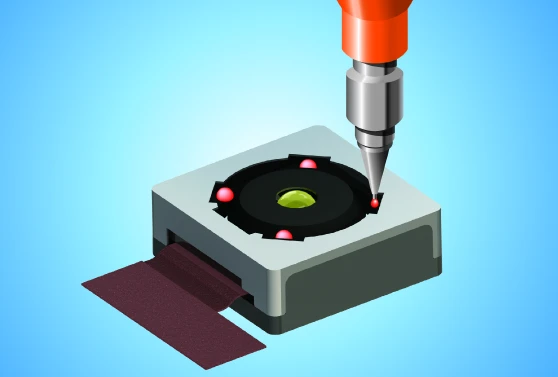

SuperHiJet application

MUSASHI AeroJet

Discover Revolutionary Non Contact Dispense Technology with the AeroJet!

The AeroJet from Musashi Engineering is at the forefront of non contact dispense technology. This jet dispenser is designed to transform your production processes with outstanding accuracy and impressive speed.

Outstanding Accuracy for Minimal Material Waste:

- Benefit from the AeroJet’s high precision, which ensures consistent quality in every application.

- Ideal for precisely applying high-viscosity materials such as underfill, silver paste, protective coatings, UV-curing adhesives, and more.

Incredible Speed for More Efficient Processes:

- Experience impressive speeds that significantly reduce cycle times.

- The flexible dispensing option allows for the application of materials from various angles, even on uneven or hard-to-reach surfaces.

Cost Efficiency Through Advanced Technology:

- By precisely controlling the amount applied, you reduce waste and increase the efficiency of your production lines.

- Advanced microcomputer control optimizes every dispensing process.

User-Friendliness and High Adaptability:

- Seamlessly switch between up to 100 channels for versatile applications across various production runs.

- The system supports ProfiNet as an optional interface and offers easy integration into your production environment.

Reliability and Support:

- Supported by Musashi’s dedicated customer service and technical support, you can rely on the sustained performance of your system.

Learn more about the AeroJet and how our innovative dispensing solutions can enhance your production efficiency.

| Applicable liquid materials: | Underfilling material, Ag paste, moisture insulation, UV bonding agent, epoxy resin, grease, flux, etc. |

| Viscosity range: | from 0.001 Pa-s (1 CPS) up to 700 Pa-s (700.000 CPS) |

| Temperature setting range: | MAX: 80 Degree Celsius |

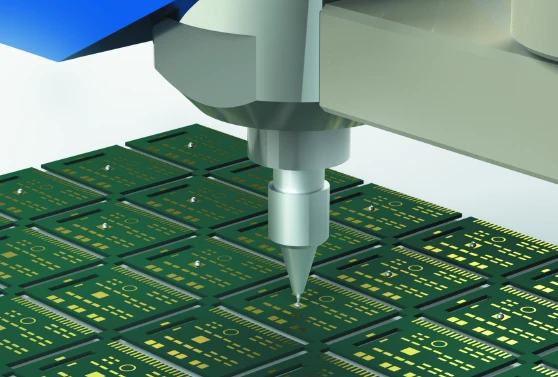

AeroJet application

MUSASHI SuperJet

Experience the Next Generation of Non Contact Dispense Technology with Musashi Engineering’s SuperJet 2

The SuperJet 2 redefines dispensing technology, designed to maximize performance and reliability in your production process. With cutting-edge technology, the SuperJet 2 combines speed, precision, and ease of use in ways that will exceed your expectations.

Reliability and Quality for Your Production Needs:

- Operating at frequencies up to 500 Hz, the SuperJet 2 is perfectly suited for fast-paced production environments.

- Easy maintenance and quick replacement of wear parts ensure minimal downtime and reduced operating costs.

Flexible and Precise Material Application:

- The SuperJet 2’s non contact dispense technology allows for precise material application from any angle, including from below, the side, or at an oblique angle.

- Especially effective for applying materials on complex, uneven surfaces or in tight spaces where traditional nozzles cannot fit.

User-Friendly Features and Enhanced Control:

- A large 3.5-inch color screen and a numeric keypad on the front panel make operation and monitoring straightforward.

- With an integrated memory function for dispensing parameters, the SuperJet 2 is easy to manage and efficient in use.

Advanced Connectivity and Easy Integration:

- Powered by a 24V DC supply from the host equipment, the SuperJet 2 is easy to integrate.

- Supports seamless integration into existing systems via USB/RS-232C and offers Profinet as an optional interface for additional flexibility.

Learn more about the SuperJet 2 and how our advanced dispensing solutions can boost your productivity.

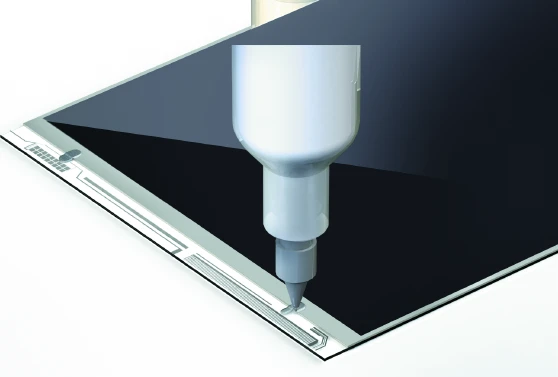

SuperJet application

Plunger dispenser

The use of our plunger dispensers guarantees highly precise dispensing of constant doses of liquids with variable viscosity. Thanks to the digital control of the plunger, our customers rely on our equipment for applications such as underfilling and potting, precisely and consistently filling with oil, injecting electrolyte solution into various types of batteries and dispensing ink. Our quality promise is always in focus, whether the application is for small or large series, or in applications in the clean room.

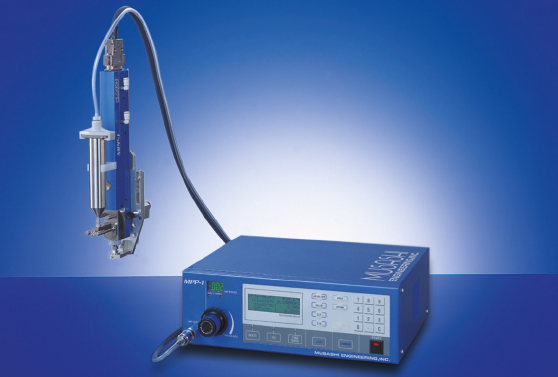

MUSASHI MPP1

Experience Ultimate Precision with the MPP-1 Measuring Master from Musashi Engineering

The MPP-1 is a volumetric, digitally controlled dispenser specially designed for the precise and consistent dispensing of fluids with varying viscosities. As a volumetric dispenser, it is ideal for applications requiring the highest accuracy, from underfill processes and LED potting to precise oil filling and electrolyte injection for various types of batteries, as well as the dispensing of pastes.

Supreme Precision for Demanding Applications:

- As a volumetric dispenser, the MPP-1 tackles the challenges of fluids ranging in viscosities from 1 to 100,000 mPa·s. Whether dealing with low-viscosity liquids or thick pastes, the MPP-1 ensures precise dispensing.

- Use it for critical applications such as LED potting or precise oil filling, as well as for battery electrolyte filling and paste dispensing.

Versatility and Easy Operation:

- Thanks to the ability to set up to 400 different dispensing parameters across multiple channels, the MPP-1 offers immense flexibility and adaptability to meet your specific production requirements.

- Tool-less maintenance and easy swapping of fluids and contact parts minimize downtime and simplify daily operations.

Robust Construction and User-Friendly Design:

- The MPP-1 is not only powerful but also designed for user convenience, facilitating quick integration into existing production lines.

- Its compact and efficient design ensures reliable operation even in demanding industrial environments.

Enhance your production efficiency and accuracy with the MPP-1 Measuring Master.

MPP1 application

MUSASHI MPP-5

Unleash Precision with Musashi MPP-5: The High-Capacity, Volumetric Digital Dispenser

Musashi Engineering is proud to present the Musashi MPP-5, a state-of-the-art dispenser designed to revolutionize your production line with its advanced digital control and high-capacity dispensing capabilities.

Key Features of the Musashi MPP-5:

- Volumetric Digital Control: Step into the future of dispensing with the MPP-5’s superior digital control system that ensures high precision and repeatability, providing the exact volume every time.

- Versatile Material Handling: Whether you’re working with low or high viscosity liquids, the MPP-5 offers quantitative dispensing with exceptional precision, handling a vast range from 0.001 Pa·s to 1000 Pa·s effortlessly.

- Comprehensive Flow Rate Range: Our lineup caters to all your needs, from small-scale precision to large-flow applications, ensuring optimal performance across a spectrum of dispensing activities.

- Advanced Error Detection: Elevate your process reliability with enhanced error detection that prevents dispensing errors, backed by improved usability for a seamless operation.

- Smart Production Management: Equipped with intelligent features like log management and self-diagnosis, the MPP-5 empowers you to keep your production smart and under control.

- Universal Container Compatibility: Adaptability is key, and the MPP-5 thrives with various liquid containers. Choose from barrels, syringes, or tank connections to match your production scale and requirements.

- Dual-Component Capability: Expanding versatility, the MPP-5 is also available for two-component materials with static mixing, allowing for a broader range of applications.

- Precision Dispensing Volumes: Achieve precise control with a minimum dispensing volume of 1µl and a maximum of 7.3 ml per stroke, embodying the pinnacle of versatility and efficiency.

Typical Applications Include:

- Potting

- Reagent Dispensing

- OCR

- Dam/Fill Processes

- Gap Filling

- Gasket CIPG/FIPG

The Musashi MPP-5 is not just a dispenser; it’s the harbinger of accuracy and efficiency. Redefine what you thought was possible in dispensing technology and give your production the competitive edge it deserves.

MUSASHI SMP III

Master Ultra-Precise Dispensing with the SMP-3 Nano Master from Musashi Engineering

The SMP-3 Nano Master sets a new standard in the field of volumetric dispensing, specifically engineered for ultra-precise applications involving solvents, volatile materials, and low-viscosity liquids. This state-of-the-art dispenser is your ultimate tool for micro-dispensing, precision dosing, and quantitative filling.

Unmatched Precision for Specialized Applications:

- Capable of handling extremely low-viscosity materials, the SMP-3 dispenses volumes as small as 1/1,000,000 mL, perfect for applications requiring meticulous detail.

- Digital control and volumetric dispensing technology ensure stable and consistent output, eliminating the risk of variability in critical processes.

Advanced Functionalities for Optimal Performance:

- Features a unique plunger mechanism and suck back function to prevent any dripping, enhancing cleanliness and accuracy in every dispensing cycle.

- Allows for continuous micro-dispensing, making it ideal for complex, repetitive tasks that demand precision.

Enhanced Usability and Control:

- Direct numerical input for dispensing volumes offers exceptional operability and reproducibility, simplifying the setup and execution of dispensing tasks.

- Equipped with a residual volume detection feature, the SMP-3 ensures efficient use of materials by alerting operators before materials run out.

Integrated and Intelligent Operations:

- Can be fully integrated with host computer systems for centralized management, facilitating streamlined operations and monitoring.

- Supports the use of micro-syringes, broadening its application across various scientific and industrial fields.

Elevate your dispensing processes with the SMP-3 Nano Master and experience unparalleled precision and control.

2 Component Dispenser

Our 2 component dispensers for faster and more flexible processing. Ideal for precision dispensing and micro dispensing of 2 component material.

MPP3-2K Dispenser

Ideally designed for precision and micro dispensing with any mixing ratio.

Special features:

- Easy maintenance

- Specific design with high durability

- Individual adjustment of the heads allows for any mixing ratio

- Compatible with 2-component materials with significantly different viscosities

Applications:

- Bonding of heatsinks with two component glue

- Potting of sensors

- Attaching waterproof connection seals

Properties:

- Gap Filler, Thermal Conductivity Pate

- 2 components resin

- Variable mixing ratios

- Precision ±1% at 25µL

- CE certified, EU RoHS compliant

MPP3-2K application

2K Dispenser Dual-Mohnomaster

Ideally suited for precision dispensing and micro dispensing at the highest speeds

Special features:

- Excellent for high speed, high flow rate and high aspect ratio sealing applications

- Product range covers micro deposits to high flow rates

- CE certified, EU RoHS compliant

Properties:

- Twin-head configuration, for high precision volume mixing

- Mixing of curing two component material

- Highly chemical resistant parts for compatibility with a wide range of liquid materials

- Product range from micro deposits to high flow rates

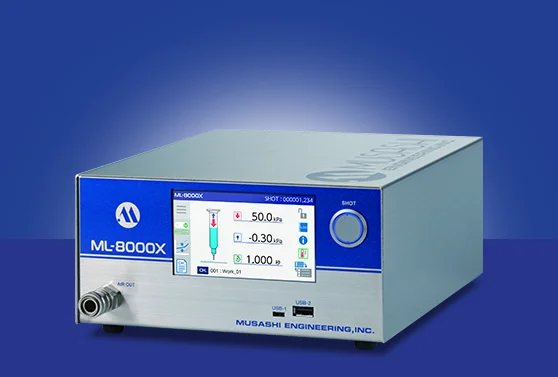

ML-8000X

The ML-8000X is a fully digitally controlled dispenser of the latest generation developed by Musashi, which fully supports the requirements of Industry 4.0.

With enhanced production management functions including automatic logging and self-diagnostics, the system supports the digital requirements of today’s modern smart factory production. Simple and intuitive operation through the 4.3-inch colour touch panel enables intuitive management of dispensing conditions and helps improve the performance of automated production lines.

- Industry 4.0 “complete” support

Instantly displays errors, logs, and the number of productions. Minimize defects by working with higher levels.

- Adjustment of parameters by time required when using a premixed two-component glue

- Recipes and channels can be imported/exported via USB port.

Easy backup to PCs and other devices.

- CE marking

- The standard range includes PNP specifications for I/O input/output signals

- Integrated Air Pulse Stabilisation (PAT) Circuitry

Screw dispenser / Cavity pump

Reliable high speed dispensing of liquids using high viscosity liquids avoiding plugging.

Our screw dispenser and cavity pump technology guarantees stable high-speed dosing of liquids such as solder paste, Ag paste, epoxy resin, grease, etc. without clogging. Here, the screw mechanism we have developed prevents both fluctuations in the dispensing quantity and the accumulation of dispensing material and enables stable and highly precise micro dose dot and line application.

ScrewMaster-3

Experience Unmatched Precision with ScrewMaster3 from Musashi Engineering

Unlock the full potential of high-performance dispensing with the ScrewMaster3, tailored for handling high-viscosity, particle-filled pastes with unparalleled precision and speed. This advanced screw dispenser is engineered for reliability in demanding industrial environments, ensuring consistent application without clogging or inconsistency.

Key Features:

- High-Speed Dispensing: Achieves rapid and accurate dispensing of materials like solder paste, epoxy resin, and thermal grease, even at high viscosities.

- Versatile Material Compatibility: Works effectively with a range of materials, including PUR hot melt, demonstrating versatility across various applications.

- Innovative Screw Mechanism: Ensures steady flow and precise micro dotting, eliminating fluid lumps and volume inconsistencies.

- Enhanced Operational Efficiency: Features like Synchro Speed™, auto-increment, and suck back prevent dripping and improve workflow.

- User-Friendly Design: Offers easy setup and maintenance, with replaceable wetted parts and intuitive digital controls.

The ScrewMaster3 is designed to boost your productivity by integrating seamlessly with desktop robots and providing real-time adjustments for flawless operations.

Discover how the ScrewMaster3 can revolutionize your dispensing process.

ScrewMaster-3 application

MohnoMaster

Discover Precision with the MohnoMaster from Musashi Engineering

The MohnoMaster is revolutionizing precision dispensing across various industries—from automotive to electronics—enhancing your production processes with its versatility.

Versatile and Adaptable:

- Perfect for dispensing fluids in a range of container sizes—from small cartridges up to 600ml cartridges, hobbocks, and large tanks.

- Ideal for precise application of sealing materials and potting, tailored to the demands of modern production lines.

State-of-the-Art Technology:

- Equipped with advanced features like Synchro Speed™ technology, enabling precise control of the dispensing process.

- The MohnoMaster supports a wide range of flow rates and is flexibly suited for diverse materials and applications.

Maximize your production efficiency and precision with the MohnoMaster.

Air pulse dispenser controller (Airpuls)

Our dispensing systems for applications in Industry 4.0

Thanks to our dispensing system controls, challenges such as dripping, pressure level deviation and residual quantity alarm in production lines are no longer an issue. Special attention is paid to fully automated and autonomously operated production, where our systems are used without any problems and perfectly fulfil their purpose of high quality dispensing.

SuperSigma CMIV

Introducing the Musashi SuperSigma CMIV: The Zenith of Air Pulse Dispensing Technology

Marc Ishikawa from Musashi Engineering proudly presents the latest breakthrough in dispensing technology – the Musashi SuperSigma CMIV. Meticulously engineered, this dispenser represents the apex of precision and efficiency in the field of air pulse dispensing, setting new benchmarks for the industry.

2. User-Friendly Interface

- Equipped with a 4.3-inch touch screen display, it offers an intuitive user experience with an outstanding user interface, simplifying configuration and operation.

3. Compact and Energy Efficient

- Eco Mode: Significantly reduces air consumption during operation.

- Standby Efficiency: Over 90% reduction in air consumption when in standby (vacuum off).

- Sleep Mode: Reduces power and air consumption during pauses, cutting standby power consumption by up to 25%.

4. Sleek Design

- 30% smaller in volume than our previous models, offering ease in integration and space efficiency.

5. Smart Factory Integration

- Enhances quality and production status visualization, and provides efficient troubleshooting analysis through remote operation capabilities.

6. Advanced Production Control

- Equipped with logging, self-diagnosis, and emergency stop features for unparalleled control and safety.

7. Network and PC Communication Compatibility

- LAN Port: For seamless network connections.

- USB Ports: Includes both Type-C and Type-A for versatile PC communications.

8. Versatile Application

- Suitable for a broad range of applications, from low to high viscosity materials.

9. Precision Dispensing

- Delivers impeccable accuracy, even in dispensing minute quantities.

The Musashi SuperSigma CMIV is not just a dispenser; it’s a testament to Musashi Engineering’s commitment to innovation, efficiency, and precision. It’s designed to elevate your production processes to new heights, seamlessly integrating into the smart factory of the future. Elevate Your Dispensing Experience with Musashi SuperSigma CMIV – Precision, Efficiency, Innovation.

For more information or to schedule a demonstration, contact Marc Ishikawa at Musashi Engineering.

ML-6000X

Everything for high quality dispensing

In the world of precision dispensing, the new generation ML-6000X stands out as a beacon of innovation and efficiency. Musashi Engineering, a name synonymous with quality and reliability, is proud to present our latest breakthrough in dispensing technology. Designed to meet the rigorous standards of Industry 4.0, the ML-6000X is engineered for those who demand precision, versatility, and connectivity in their manufacturing processes.

High Precision Digital Dispenser: The ML-6000X is not just a dispenser; it’s the epitome of precision. Installed with our patented air-pulse stabilizing circuit, this state-of-the-art machine eliminates volume fluctuation, ensuring unparalleled dispensing accuracy every time.

Next-Generation Capabilities: Equipped with an array of next-generation functions, the ML-6000X caters to diverse operational needs. From its basic log function and interval dispensing to advanced channel registration and switching, this machine is designed to streamline your processes. Additionally, its various error and alarm outputs ensure that you stay informed and in control, minimizing downtime and enhancing productivity.

User-Friendly Design: We believe that high-tech should not mean high-complication. That’s why the ML-6000X features a user-friendly LCD display, making setting adjustments and operation as simple as possible. Its compact size ensures that it fits seamlessly into any workspace, providing powerful dispensing capabilities without occupying valuable space.

Versatile Application: Whether you require high-quality hand dispensing or seek the efficiency of automated dispensing with robots, the ML-6000X is your solution. Its excellent dispensing capability makes it suitable for a wide range of applications, ensuring that your production needs are not just met, but exceeded.

Basic Functions, Advanced Performance: With its basic remaining volume detection function, the ML-6000X takes the guesswork out of operations, allowing for uninterrupted productivity. The variety of channel registration feasibility opens up new possibilities for customization and efficiency, tailored to your specific requirements.

Ready for Industry 4.0: In today’s fast-evolving industrial landscape, readiness for Industry 4.0 is not just an option—it’s a necessity. The ML-6000X is designed with this in mind, ensuring seamless integration into smart factories and automated systems.

Discover the difference that precision engineering can make in your production line. Choose the ML-6000X from Musashi Engineering for a future where accuracy, efficiency, and connectivity converge. Welcome to the new standard in precision dispensing.